Permanent Exhibits

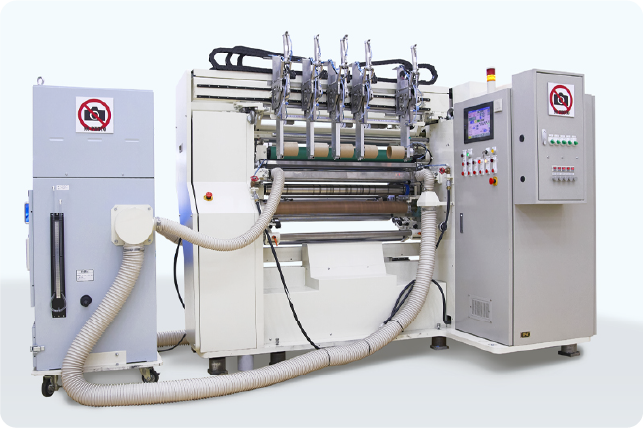

WS303

Independent arm slitter

| Material to be machined | Separator film, etc. |

|---|---|

| Material thickness | Min. 0.008 mm - Max. 0.040 mm |

| Winding diameter | Max. φ350 mm |

| Winding width | Min. 35 mm - Max. 300 mm |

| Winding core | 3B |

| Winding speed | Max. 150 m/min |

| Winding contact pressure | Adjustable by pressure reducing valve |

| Contact roller | Contact or near |

- Independent arm slitting machine for LIB separator

- Independent arm individual control system,

independent arm horizontal transfer system,

slit blade vertical drive system - The slit system can be selected from either the

"groove leather cut system" or "shear cut system".

Main Features

Tension and contact pressure can be set individually for each independent arm.

Mixed winding of different widths is possible.

Contact winding or gap winding can be selected.

Horizontal transfer of independent arms keeps contact pressure control free from the influence of product tare weight.

The film pass length is constant from the beginning to the end of winding, and the end surface of the wound product is excellent.

Because both the upper and lower shear cutter blades are driven, sharpness is excellent.

WS151

Slitter for optical film

| Applicable films | PET, PI, PA, TAC, etc. High-functional films |

|---|---|

| Original fabric/ film diameter | Max. φ800 mm (replacement core 3B, 6B) |

| Original fabric/ film width | 300 mm - 1,100 mm |

| Winding diameter | Max. φ450 mm |

| Winding width | 300 mm - 1,100 mm (replacement core for both 3B and 6B) |

| Number of cuts | 1 - 2 winds |

| Winding speed | Max. 400 mm |

| Winding tension | 15 - 200 N/m |

| Contact pressure | 40 - 600 N/m |

- This highly functional optical film slitter is capable of performing slit tests and acquiring various data.

- It can perform diagnosis of proper tension cut, diagnosis of proper contact pressure, confirmation of the proper slitting system, and more.

- Cleanroom compatible

Main Features

Diagnosis of proper tension cut:

Selectable out of the S-hanging roller system/

suction roller system

Diagnosis of appropriate tension value:

With unwinding/winding tension display and feedback function

Diagnosis of proper contact pressure:

Selectable out of touch winding/near winding and tandem touch roller

Confirmation of proper slitting method:

Verification of material, diameter, drive system,

depth of cut, contact pressure, etc. for each leather blade, round blade, and shear blade

C530

Rotation winder

| Winding diameter | Max. 600 mm |

|---|---|

| Winding width | 1,100 mm |

| Winding core | 3B |

| Winding speed | Max. 600 mm |

- "High-quality winding" and "No-loss winding" for high-functional, high-value-added webs

- Realization of slitter-class winding quality

- Minimization of loss during product rewinding

Main Features

Equipped with a horizontally movable winding head to maintain constant web posture.

(Slitter-class winding quality)

Equipped with twin winding heads and corresponding contact rollers

(for minimizing rewinding loss)

Simplified signal and drive system based on slipring-less winding system

(slitter-class winding quality)

The cutting and rewinding system can be selected according to web characteristics

(near-core/on-core/guillotine cut, etc.)

We conduct tests and experiments using the above exhibited machines and test equipment at no charge.

Please contact our sales office in advance if you wish to have a test.

(We ask that you prepare original fabrics/films, paper tubes, etc.)