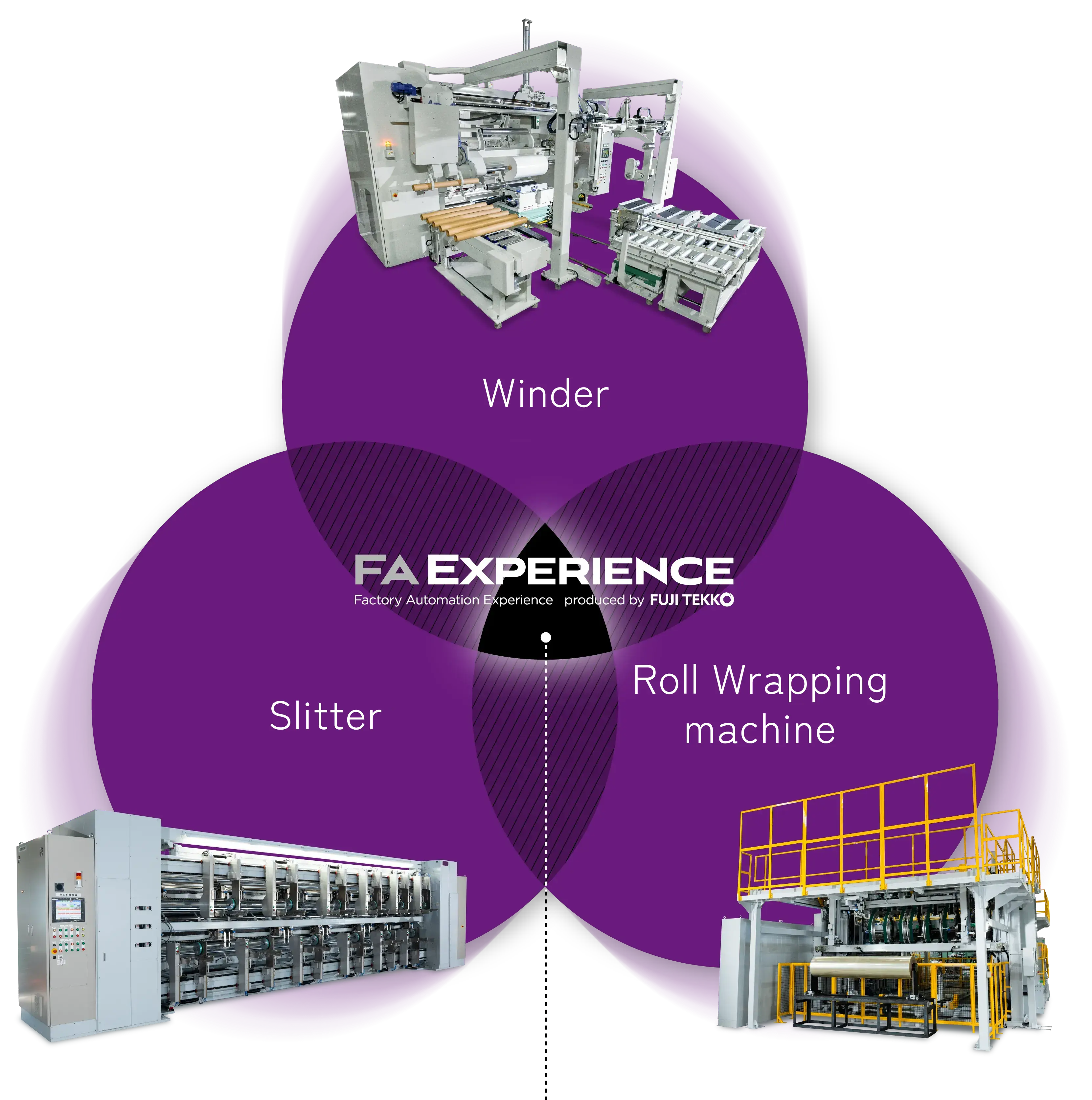

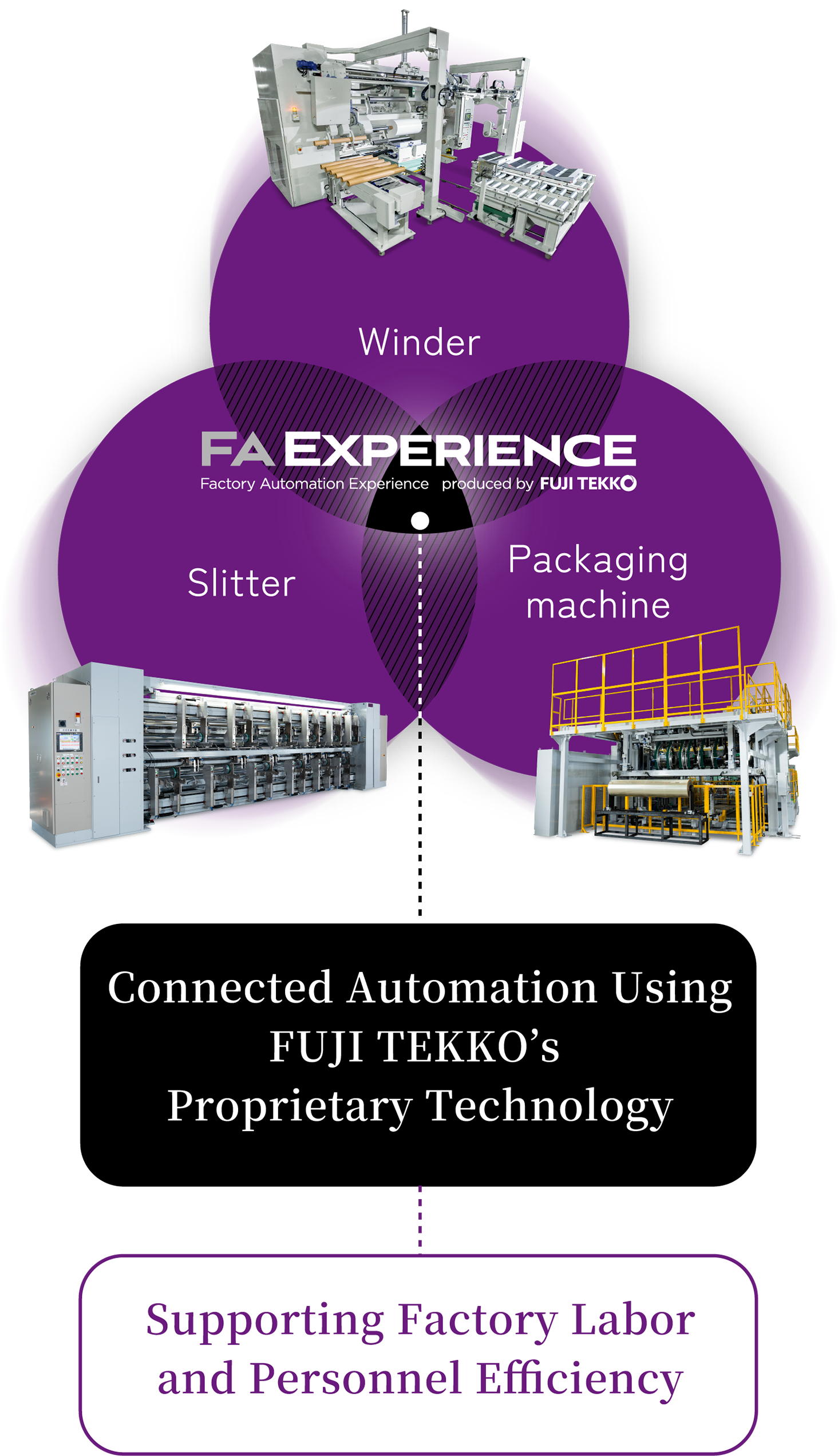

Solution

Only FUJI TEKKO can offer a completely

integrated and automated system

for winding, slitting, and packaging.

Our ability to handle all three—winders, slitters, and packaging machines—enables us to deliver a unique

and unmatched experience. By organically linking each process based on customer needs,

we provide full one-stop automation, helping factories save labor

and reduce staffing while significantly boosting performance.

R&D Organization

Everything We Do Is for Our Customers

—and the Society Beyond

To stay ahead of the curve as new web materials are developed and brought to market each year,

FUJI TEKKO has established an in-house R&D division. We focus on developing advanced technologies

that other companies cannot replicate. As a leading member of the Web Handling Technology Study Group ,

a collaboration between industry and academia, we also contribute to advancing

web handling theory and conducting practical validation, helping to elevate industry-wide technical standards.

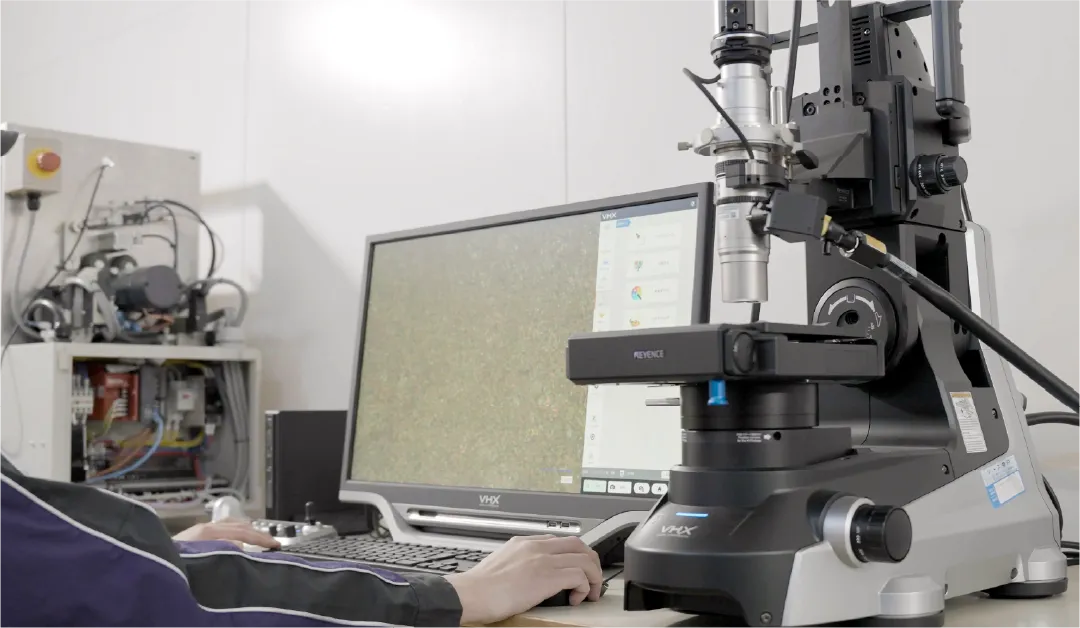

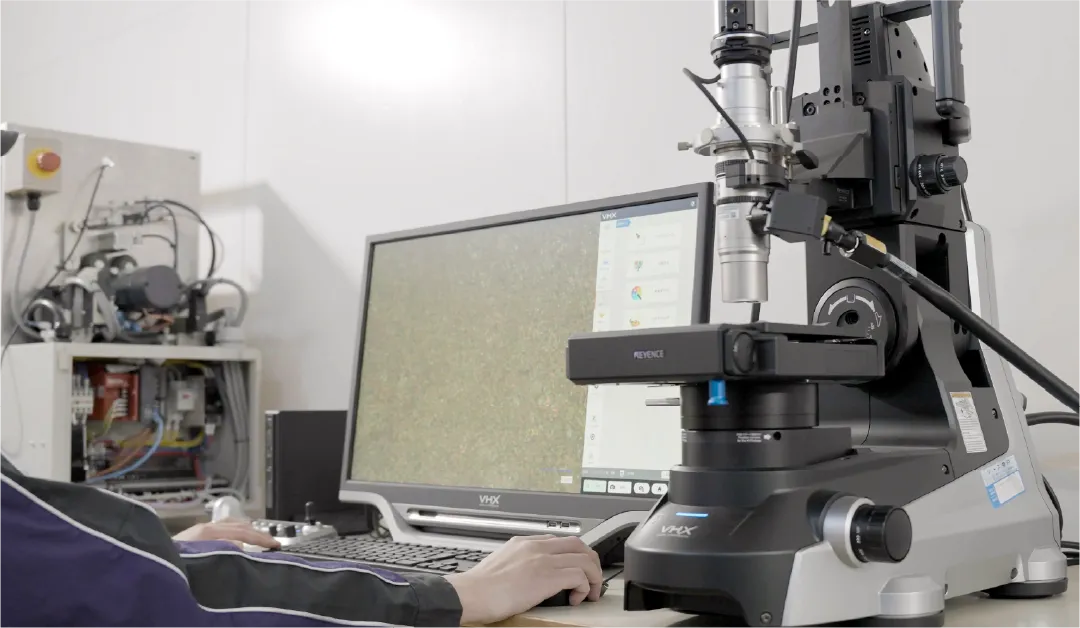

R&D Facility

At our R&D facility in Katano Second Factory , we analyze and study new materials requested by our customers. When necessary, we also develop prototype machines at full production scale to verify the required performance and quality, leading to the development and delivery of high-performance, high-quality machines.

- Qualified

personnel - Mechanical design/

Nationally accredited first-class

certified technicians:17Electrical design/

Nationally accredited first-class

certified technicians:11

- Patents and

utility models - Patents/Domestic:208 Overseas:50

Utility models/Domestic:105

Production Division

In-House Integrated Production System

for Maximum Performance and Quality

At our three factories, each Production Division follows a fully integrated production process

from part processing to final assembly after an order is confirmed.

By adhering to a “complete shipment of complete products ” model, we eliminate excess inventory

and maximize efficiency in both cost and space,

while delivering original, high-performance, high-quality manufacturing.

Assembly Plant

This plant can accommodate large machines with a total length of

42 meters as well as FA systems consisting of multiple devices.

Parts Machining Plant

In order to meet short delivery times while emphasizing

performance and quality, we conduct almost 100% of critical machine

parts fabrication and control system construction in-house.

To achieve this, we have installed the following facilities.

Facilities

- Can manufacturing and sheet metal fabrication equipment

- Vertical machining center

- Large 5-face machining center

- Vertical boring and milling machine

- Horizontal boring and milling machine

- Radial drilling machine

- Portable radial drilling machine

- Vertical drilling machine

- Large long lathe

- General-purpose lathe

- Multitasking machine

- NC lathe